- B2B Metal and Engineering Marketplace

- Alloy Steel

- Aluminium

- Carbon Steel

- Copper Alloy

- Hardox Plate

- Metal Cutting Services

- Nickel Alloy

- Plastic Mould Steel

- Precision Ground Plate

- Stainless Steel

- Stainless Steel Shim Plate , Carbon Steel Shim Plate

- Structure Steel

- Titanium

- Tool Steel

- Others

E STEEL SDN. BHD.

3, Lorong Sungai Puloh 7/KU6, Kawasan Perindustrian Sungai Puloh, 42100 Klang, Selangor, Malaysia.

+603-3292 8686

Metal Heat Treatment Services , Hardening and Tempering Services

| Previous | 3 / 4 | Next |

E Steel works as Global Metal Procurement Company , B2B Marketplace with Metal Suppliers

For Metal Heat Treatment Services Suppliers and Vendors, Heat Treatment Hardening Vendors in Malaysia , please refer to our partner with this link : https://welcome.smemetal.com/en/catagories?page=1&state=&city=&tag=12

E Steel has partners and vendors with Heat Treatment Services Providers in Malaysia , providing Hardening Heat Treatment Services , Induction Heat Treatment Services , Case Hardening Heat Treatment , Annealing / Tempering Heat Treatment Process.

-

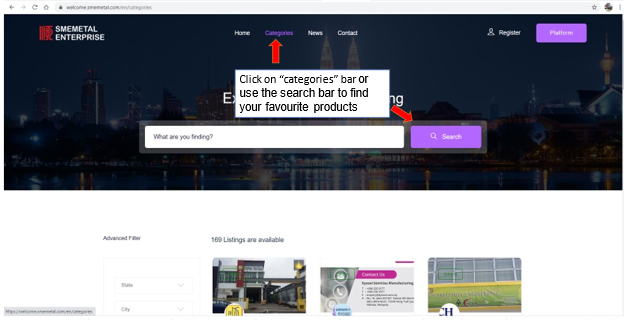

What is SME Metal B2B Marketplace Metal Platform ? - You may watch this - https://www.youtube.

com/watch?v=zgqZJ7S2pf0

- How to make inquiry on SME Metal (A Metal & Engineering Services B2B Marketplace) :

- Browse through our various categories or use the search bar (Heat Treatment Services / Heat Treatment) to find the suppliers and vendors for heat treatment services.

- You may choose from your states & cities to find out your Heat Treatment Services Suppliers as well.

- Choose your preferred Heat Treatment Services Vendors on our B2B Marketplace

-

On the seller / supplier description page , you can either click on ''Call Now'' to discuss or Send An Inquiry to the Heat Treatment Providers

----------------------------------------------------- ------------------------------- ------------------------------------

Description

Heat Treatment Services Suppliers - Heat Treatment Hardening Services / Through Hardening Services

To produce the most durable parts with clean surface and minimum distortion.Through hardening is the process of using a rapid quench to increase hardness throughout a steel alloy for the purpose of increasing its strength. As opposed to case hardening, which gives steel a hard outer layer while preserving a softer, more ductile core, through hardening diffuses carbon throughout the entire section of steel.

Through Hardening Heat Treatment Services is useful for applications where strength, hardness and wear-resistance are desired.

Induction Heat Treatment Services

Induction heating is often used in the heat treatment of metal items. The most common applications are induction hardening of steel parts, induction soldering/brazing as a means of joining metal components and induction annealing to selectively soften an area of a steel part.Case Hardening Heat Treatment Services

Case hardening is a term used to describe several, more specific procedures which involve the addition of carbon or carbon and nitrogen to the surface of steel. This is done to give the material a hard, wear-resistant outer layer while preserving a softer, more ductile core that is better able to respond to stress without cracking. Case hardening allows manufacturers to work with softer materials and still meet basic requirements for hardness required by an application.Annealing Heat Treatment , Normalising Services

The annealing process is performed to relieve the internal stresses that have occurred during the rolling process. The temperature inside the annealing furnace reaches 400–600°C, which is sustained for 1.5 hours using LPG bottles or diesel as fuel. The annealing process is done two or three times before reaching the cutting stage, and after longitudinal stretching, transversal stretching, and cutting into circular discs. The number of times the annealing process is repeated depends on production and furnace capacities.Other Heat Treatment , Hardening Services including :

Vacuum Hardening , Shot Blasting , Subzero Proce* At SMEMETAL.COM, you may find your suitable Metal Heat Treatment Services , Heat Treatment Hardening Services , Though Hardening Services , Induction Heat Treatment Services , Case Hardening Heat Treatment Services , Annealing Heat Treatment Services and other Heat Treatment Hardening Services Suppliers.

Our Sales & Supplier Network

E Steel has a Wide Global Sourcing and Sales Networking including :

Australia, Pakistan, Malaysia, Singapore, Taiwan, China,Vietnam, Belgium, Japan, South Korea, Philippines, France, United Kingdom, Indonesia, Thailand, Hong Kong, China, Sweden, United States, Dubai, Finland, Brunei,Germany.